Showroom

Borosilicate glass, valued for heat resistance and clarity, serves varied roles like reflex gauge and industrial sight glasses. Crafted from silica and boron oxide, it offers a sleek, transparent finish. With minimal thermal expansion, it withstands extreme temperatures and chemicals, suitable for lab equipment, cookware, and architecture, ensuring enduring performance.

Aluminosilicate glass blends aluminum oxide and silicon dioxide with precision, resulting in a durable, versatile material. Resistant to thermal shock and mechanical stress, it offers high transparency, low distortion, and scratch resistance. Widely used in electronics for thermal insulation, it's also ideal for harsh environments like laboratories and industry due to chemical resistance.

Quartz glass, or fused quartz, is made from pure silicon dioxide, providing exceptional clarity and thermal resilience. Melted at high temperatures, it's shaped and polished meticulously for flawless results. Resistant to heat, corrosion, and electrical conductivity, it's versatile for scientific instruments, semiconductors, and optical devices. Its low thermal expansion is crucial for precision tasks like optical lenses and lab equipment.

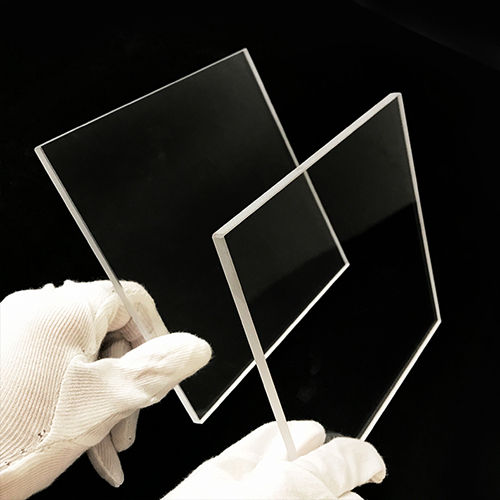

A square glass plate, made from soda-lime or borosilicate glass, features smooth edges and a polished finish, crafted with precision cutting and grinding. Strong and durable, it withstands impacts and thermal shocks, finding versatile use in serving trays, decorations, and architecture. Customizable in size and thickness, its flat surface allows for easy printing or engraving.

Glass hole drilling creates precise openings using diamond-tipped drill bits or lasers, typically post-tempering for strength. Meticulously controlled speed and pressure prevent cracking. Finished holes are smooth, often polished for aesthetics. Applied in architecture, furniture, and automotive sectors, it enhances shower doors, glass shelves, and balustrades, blending functionality with seamless aesthetics.

Glass tempering is a process to strengthen glass by heating it to high temperatures and then rapidly cooling it. This creates internal stress, increasing its strength and making it more resistant to breakage. Tempered glass is used in construction, automotive, and electronics industries for safety, durability, and thermal resistance.

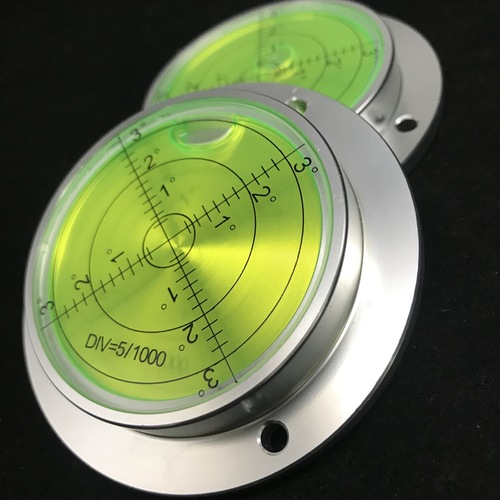

Glass applications span industries, shaped through techniques like blowing, casting, or molding, yielding varied forms from bottles to sculptures. Finishes range from smooth to textured, suiting diverse needs. Despite brittleness, technological advancements enhance strength for architectural, automotive, and security uses. Attributes include transparency, corrosion resistance, fitting construction, transportation, packaging, and art, blending functionality with aesthetics.

Back to top